The Award Ceremony(Left: MHI Thermal Systems, Right: MHI)

TOKYO, Jan 28, 2026 – (JCN Newswire via SeaPRwire.com) – Mitsubishi Heavy Industries, Ltd. (MHI) has been recognized with awards at the 2025 Energy Conservation Grand Prize awards, organized by the Energy Conservation Center, Japan (ECCJ) and sponsored by the Ministry of Economy, Trade and Industry (METI). Mitsubishi Heavy Industries Thermal Systems, Ltd. (MHI Thermal Systems), a part of Mitsubishi Heavy Industries (MHI) Group, received the Minister of Economy, Trade and Industry Award, the highest award in the Products and Business Models Category (Business Field), for its JHT-Y/JHT-YI series of large-capacity centrifugal chillers adopting a low-GWP refrigerant. In addition, the Oye Plant at the Nagoya Aerospace Systems Works, part of MHI’s Commercial Aviation Systems segment, received the Agency for Natural Resources and Energy Commissioner’s Award in the Energy Conservation Case Study Category (Transport Field) for its “Energy Conservation Activities to Achieve MISSION NET ZERO: Endeavors at an Aerospace Parts Factory.” The award ceremony was held in Tokyo on January 28th.

The Energy Conservation Grand Prize awards are presented to Japanese companies, local governments, and educational institutions, recognizing examples of initiatives for energy savings, as well as highly energy-efficient products and business models. The awards aim to foster greater awareness of energy conservation, promote the widespread adoption of energy-saving products, and contribute to the realization of an energy-efficient world. MHI Thermal Systems has received awards numerous times, including the 2024 Agency for Natural Resources and Energy Commissioner’s Award for its TEJ35AM electric-driven transport refrigeration unit for the ELF electric truck.(*1)

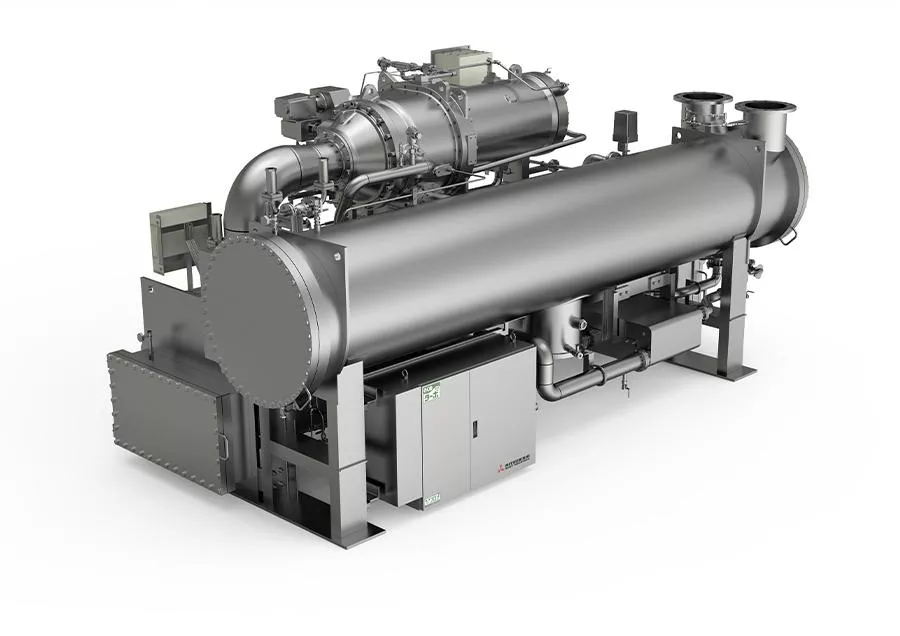

The JHT-Y (constant-speed type) and JHT-YI (inverter type), which received the Minister of Economy, Trade and Industry Award this time, are large-capacity centrifugal chillers that utilize the refrigerant HFO-1234yf, which has a very low environmental impact with a GWP(*2) of less than 1. Centrifugal chillers are heat source equipment that generate chilled water with high efficiency. The adoption of a newly designed compressor provides a rated COP(*3) of up to 6.4, while the inverter-equipped model achieves high-efficiency operation with an IPLV(*4) of 8.8, and a maximum COP of 24.9 at partial load. In addition, upgrading to this series from existing products using HFC refrigerants (a CFC substitute), which have high GWP ratings, can reduce electricity consumption and CO₂ emissions by approximately 20% per year. As a result, this series is widely adopted in factories and district heating and cooling systems for air-conditioning and industrial process applications.

The JHT-Y (constant-speed type) and JHT-YI (inverter type), which received the Minister of Economy, Trade and Industry Award this time, are large-capacity centrifugal chillers that utilize the refrigerant HFO-1234yf, which has a very low environmental impact with a GWP(*2) of less than 1. Centrifugal chillers are heat source equipment that generate chilled water with high efficiency. The adoption of a newly designed compressor provides a rated COP(*3) of up to 6.4, while the inverter-equipped model achieves high-efficiency operation with an IPLV(*4) of 8.8, and a maximum COP of 24.9 at partial load. In addition, upgrading to this series from existing products using HFC refrigerants (a CFC substitute), which have high GWP ratings, can reduce electricity consumption and CO₂ emissions by approximately 20% per year. As a result, this series is widely adopted in factories and district heating and cooling systems for air-conditioning and industrial process applications.

The Oye Plant, which received the Agency for Natural Resources and Energy Commissioner’s Award, is a historic production facility that includes buildings that are over 80 years old. Since the main wings and fuselages of commercial aircrafts are manufactured under strict quality control, there are many constraints on energy conservation. Under such conditions, in the wake of MHI Group’s declaration to achieve its MISSION NET ZERO plan for carbon neutrality by 2040, MHI began implementing energy-saving initiatives under a new system from fiscal 2021. The first stage focused on eliminating waste by conducting energy-efficiency patrols monitoring all equipment in the plant, while in the second stage, the heat treatment furnaces were repaired and automated to enhance the thermal efficiency rate. For the third stage, cross-functional teams developed novel equipment diagnosis tools, and utilized a scientific approach to achieve overall optimization. As a result, in fiscal 2024, MHI achieved energy savings of 18% per unit of output,(*5) and CO₂ reductions of 4,200 tons, compared to fiscal 2021 levels. This efficiency scheme has been standardized, allowing it to be implemented at other locations. Promoting energy conservation with minimal investment while maintaining productivity and quality, the program was recognized for its sustainability, as well as its versatility and spillover effects.

The Oye Plant, which received the Agency for Natural Resources and Energy Commissioner’s Award, is a historic production facility that includes buildings that are over 80 years old. Since the main wings and fuselages of commercial aircrafts are manufactured under strict quality control, there are many constraints on energy conservation. Under such conditions, in the wake of MHI Group’s declaration to achieve its MISSION NET ZERO plan for carbon neutrality by 2040, MHI began implementing energy-saving initiatives under a new system from fiscal 2021. The first stage focused on eliminating waste by conducting energy-efficiency patrols monitoring all equipment in the plant, while in the second stage, the heat treatment furnaces were repaired and automated to enhance the thermal efficiency rate. For the third stage, cross-functional teams developed novel equipment diagnosis tools, and utilized a scientific approach to achieve overall optimization. As a result, in fiscal 2024, MHI achieved energy savings of 18% per unit of output,(*5) and CO₂ reductions of 4,200 tons, compared to fiscal 2021 levels. This efficiency scheme has been standardized, allowing it to be implemented at other locations. Promoting energy conservation with minimal investment while maintaining productivity and quality, the program was recognized for its sustainability, as well as its versatility and spillover effects.

Encouraged by these awards, MHI Thermal Systems and MHI will continue to develop technologies and products that further reduce CO2 emissions and contribute to energy efficiency. In addition, MHI Group will leverage the synergies generated by its broad range of business areas to further focus on providing optimal solutions that meet the diverse needs of customers.

(*1) For further information on MHI Thermal Systems’ 2024 Energy Conservation Grand Prize, see the following press release. https://www.mhi.com/news/25013002.html

(*2) Global Warming Potential (GWP) is a coefficient of the greenhouse effect of a gas relative to carbon dioxide (CO2), which has a fixed GWP of 1.0. Smaller values indicate a lower greenhouse effect, and better environmental performance. For further information on the JHT-Y/JHT-YI series, see the following press release. https://www.mhi.com/news/220405.html

(*3) Coefficient of performance (COP) is a performance coefficient calculated based on Japanese Industrial Standards (JIS). Higher values indicate greater energy efficiency.

(*4) Integrated part load value (IPLV) is an indicator of the efficiency of air conditioning equipment during partial load operation. Higher values indicate greater energy efficiency.

(*5) Oil equivalent reduction of 2,074 kiloliters per year. The standardization of the practices at the Oye Plant and implementation at other MHI Group production facilities in Japan is expected to provide total reductions of up to 12,000 kiloliters per year.

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world’s leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.

Copyright 2026 JCN Newswire via SeaPRwire.com. All rights reserved. www.jcnnewswire.com